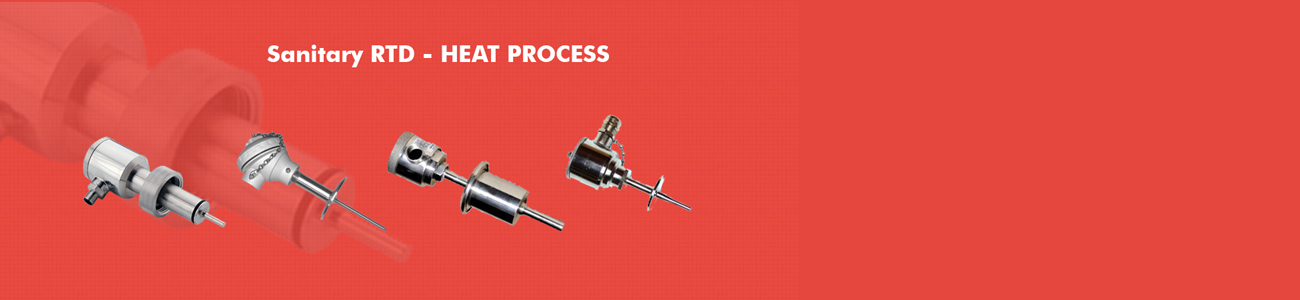

Designed to meet the strict quality standards of high hygiene environments, HPI sanitary RTD sensors are ideal for food, dairy, beverage, pharmaceuticals and chemical process. With a choice of process connections, cable options, and other customisations, we have something for every application here! The RTD sensor's 2, 3 or 4-wire platinum element can be constructed in simplex or duplex assembly. The RTDs can measure temperatures between -50 and 250°.

Sanitary RTD sensors with threaded female nuts are built for food, dairy, beverage, pharmaceutical and chemical industries, where maintenance of hygiene is critical in order to prevent contamination. The female nut is designed, so that no thread is exposed, thereby preventing any contaminant buildup. Its threaded female nut is made of SS316L grade material. The RTD sensor is built with SS316L sheath. As the sheath does not bend, a sheath length greater than 300 mm is not recommended. The sheath terminates into a die cast, weatherproof aluminium head. The RTD sensors measure temperatures between -50 and 250°C. Its 2, 3 or 4 wire Pt100 RTD element can be constructed in single or dual assembly in Class A/Class B as per the IEC 751 standard for RTD sensors. The terminal head of the RTD sensors has a standard 1/2” BSP (F) single cable entry and a single compression cable gland with the option of dual cable entry and double compression glands.

Sanitary RTD sensors with tri clover connections and a head type terminations, are built for food, dairy, beverage, pharmaceutical and chemical industries, where maintenance of hygiene is critical in order to prevent contamination. Tri clover connections offers a clean and hygienic connection, designed to be clean in place (CIP). It is constructed to have no exposed thread connections and no abrupt changes in the structure, thereby preventing any contaminant buildup. Triclover connections are made of SS316L, built in 0.5”, 1” and 1.5 “ sizes. The RTD sensor is built with SS316L sheath. As the sheath does not bend, a sheath length greater than 300 mm is not recommended. The sheath terminates into a die cast, weatherproof aluminium head. The termination head is also available in a range of other materials. The sensor measure temperatures between -50 and 250°C. Its 2, 3 or 4 wire Pt100 RTD element can be constructed in single or dual assembly in Class A/Class B as per the IEC 751 standard for RTD sensors. The terminal head of the RTD sensors has a standard 1/2” BSP (F) single cable entry and a single compression cable gland.